Forklifts are essential to the smooth operation of warehouses, factories, and shipping yards. But behind every lift and shift lies a critical component that keeps these machines grounded—literally. The counterweight. While it may appear as a simple metal block, the counterweight plays a pivotal role in ensuring stability, safety, and efficiency in lifting operations.

With rapid industrialization, evolving material handling needs, and the push for electric forklifts, the demand for advanced and precisely engineered counterweights is growing. The focus is no longer on mere mass but on material optimization, design integration, and sustainability.

According to Marketintelo, “The global Forklift Counterweight Market size was valued at approximately USD 7.5 billion in 2024 and is projected to reach USD 10.9 billion by 2032, growing at a compound annual growth rate (CAGR) of 4.8% during the forecast period 2024–2032.”

Read Full Research Study – https://marketintelo.com/report/forklift-counterweight-market

What Exactly Is a Forklift Counterweight?

At its core, a forklift counterweight is a heavy mass—typically made of cast iron, steel, or composite materials—located at the rear of the vehicle. Its primary function is to balance the load being lifted at the front. Without a counterweight, a forklift would easily tip over when handling heavy goods.

In modern forklifts, the design and placement of counterweights are meticulously engineered to optimize space, maintain a low center of gravity, and enhance maneuverability. As forklifts are increasingly deployed in tighter spaces and on uneven surfaces, the demand for more compact yet effective counterweights has surged.

Material Innovation: Beyond Just Heavy Metal

Traditionally, counterweights have been composed of cast iron due to its density and cost-effectiveness. However, modern manufacturing trends are pushing boundaries.

Composite materials, including concrete-metal hybrids and lead-based alloys, are being explored to reduce size while maintaining effectiveness. Moreover, with sustainability becoming a priority, manufacturers are increasingly turning to recycled materials for producing counterweights. This move not only lowers carbon footprints but also cuts down material costs.

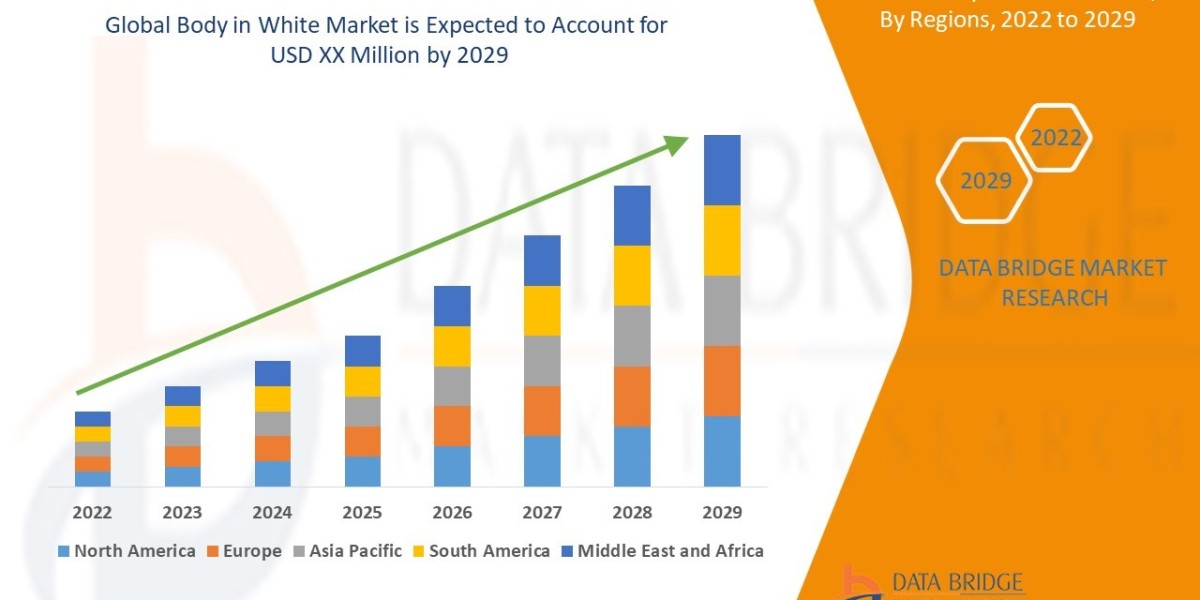

As per Dataintelo’s analysis, “The regional distribution of the Forklift Counterweight Market

reflects varying consumer preferences, market shares, and growth rates. For instance, Europe accounted for approximately 27% of the market share in 2024, generating close to USD 2.02 billion.”

Read Full Research Study – https://dataintelo.com/report/forklift-counterweight-market

The EV Push and Its Impact on Counterweight Design

As with the automotive sector, electrification is transforming forklifts. Electric forklifts offer quieter operation, zero emissions, and reduced maintenance costs—features that are increasingly appealing to logistics and warehousing firms.

However, electric forklift batteries are often heavy and positioned at the rear of the vehicle. This weight can double as a counterweight, prompting engineers to rethink the need for traditional metal blocks. While in some cases, batteries can fully replace counterweights, in others, a hybrid approach is necessary.

This dual-use of battery systems is giving rise to integrated counterweight designs that improve balance without unnecessarily increasing the vehicle's total mass. As a result, the market is seeing growing interest in modular and customizable counterweight solutions that accommodate diverse forklift configurations.

Regional Shifts and Manufacturing Trends

Asia Pacific Leads the Volume Race

With manufacturing hubs in China, India, and Southeast Asia, the Asia Pacific region dominates the forklift counterweight market in terms of volume. A booming e-commerce sector and government infrastructure projects have significantly increased demand for warehouse and material-handling equipment.

In China alone, annual forklift production exceeds one million units, and domestic manufacturers are increasingly investing in cost-efficient counterweight solutions to support export demands.

Europe and North America Focus on Efficiency

In contrast, Europe and North America are more focused on technological integration, efficiency, and environmental compliance. The push for sustainable materials and electric forklifts in these regions is resulting in demand for lightweight and recyclable counterweight materials.

Regulatory frameworks, especially in the EU, are also influencing design mandates, requiring noise reduction, emissions control, and ergonomic balance—which all indirectly affect counterweight design.

Challenges in the Market

While the market outlook appears promising, several challenges persist:

High Raw Material Costs: Fluctuations in the cost of iron, steel, and lead impact profit margins.

Environmental Regulations: Especially in Europe, strict rules around lead and emissions are pressuring manufacturers to innovate faster.

Design Complexity: As forklift designs become more compact and agile, designing the right counterweight without compromising stability is increasingly complex.

Integration with EV Systems: Not all forklifts can accommodate integrated battery-counterweight designs, limiting mass adoption.

Opportunities for Innovation

Despite these challenges, numerous growth opportunities are emerging:

3D-Printed Counterweights: Emerging as a promising niche, additive manufacturing can allow for precision-designed, custom-shaped counterweights suited to unique forklift models.

Smart Counterweights: Integration of sensors for weight distribution and stress analysis could allow real-time stability monitoring, particularly beneficial in high-risk environments.

Circular Economy Practices: Reusing materials from decommissioned machinery to create new counterweights supports sustainability while reducing costs.

Customization Is Becoming the Norm

Forklift manufacturers are increasingly demanding customized counterweight solutions tailored to specific models and operational requirements. From weight specifications to material choices and shape designs, the market is shifting toward collaborative development between forklift OEMs and counterweight suppliers.

This trend is especially noticeable in premium forklift segments, where balancing performance, efficiency, and aesthetics is critical. Customized counterweights also support branding—some manufacturers emboss logos or brand-specific designs into the weight blocks.

Role of Automation and Robotics in Production

Automation is streamlining counterweight manufacturing processes. Advanced robotic systems can now handle mold casting, finishing, and even quality inspection. This automation ensures precision, reduces labor costs, and improves turnaround times.

Furthermore, automated inventory tracking and order management systems are helping suppliers respond more quickly to OEM demands, minimizing production delays.

The Road Ahead: What to Expect

As warehouse automation, electrification, and compact vehicle design accelerate, the need for smarter, lighter, and more sustainable counterweight solutions will only grow. Material innovation and design adaptability will be key differentiators for suppliers looking to secure long-term OEM partnerships.

The market is also likely to witness increased collaboration between counterweight producers and forklift manufacturers to co-develop integrated chassis-counterweight systems. This kind of synergy will not only enhance performance but also streamline production and reduce end-user costs.

Final Thoughts

While forklift counterweights may not often take the spotlight, they are undeniably a cornerstone of forklift functionality and safety. The evolving demands of logistics, the rise of electric vehicles, and regulatory shifts are all catalyzing innovations in this once-static component.

From traditional cast iron blocks to smart, integrated designs made from recycled composites, counterweights are undergoing a quiet but impactful transformation—one that is foundational to the future of material handling.