A mechatronic design engineer is a multidisciplinary professional who integrates mechanical engineering, electronics, control systems, and software to design and develop intelligent, automated systems. By combining expertise in these fields, mechatronic design engineers create innovative solutions for industries like robotics, automotive, aerospace, and manufacturing. Their work ensures systems are precise, efficient, and reliable, meeting modern demands for automation and sustainability. This 800-word overview explores the role, responsibilities, applications, skills, challenges, and future trends of mechatronic design engineering.

Role and Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers are responsible for creating and optimizing complex systems through a blend of engineering disciplines:

System Design and Modeling: They use CAD software (e.g., SolidWorks) and simulation tools like MATLAB/Simulink to design and model mechanical components, electronic circuits, and control algorithms, ensuring integrated system performance.

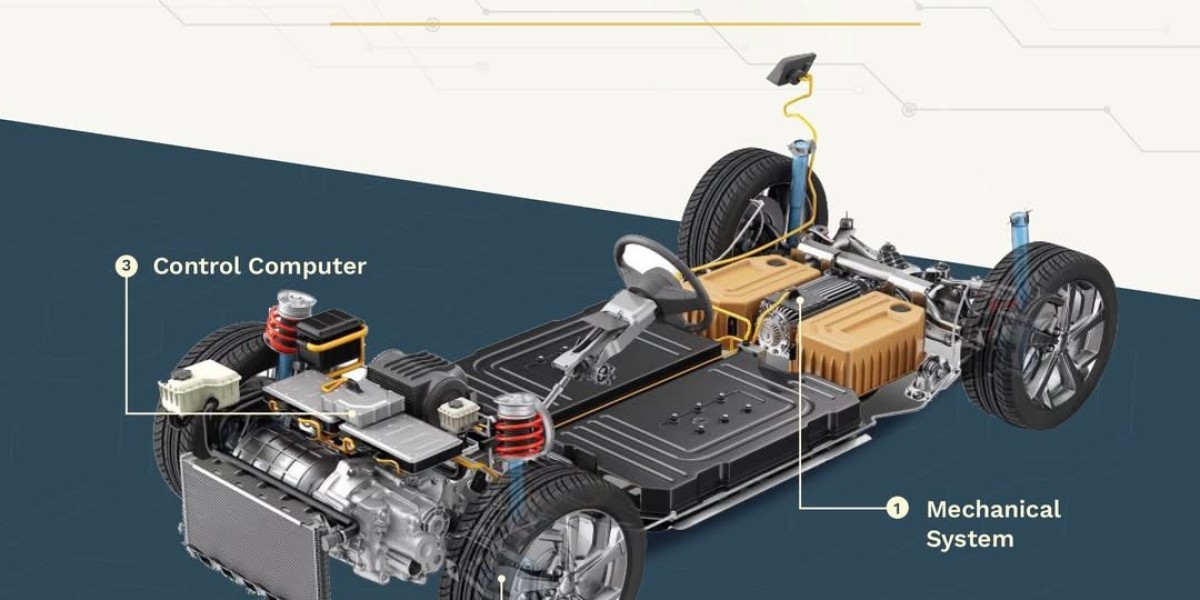

Sensor and Actuator Integration: Engineers select and integrate sensors (e.g., gyroscopes, pressure sensors) and actuators (e.g., motors, hydraulics) to enable precise monitoring and control of system behavior.

Control System Development: They design algorithms, such as PID or Model Predictive Control, to regulate system dynamics, ensuring stability and responsiveness in real-time applications.

Embedded Software Development: Writing firmware in C/C++ or using real-time operating systems (RTOS), engineers program microcontrollers to manage hardware interactions and execute control logic.

Prototyping and Testing: Mechatronic design engineers build prototypes and conduct tests, including Hardware-in-the-Loop (HIL) simulations, to validate system performance under real-world conditions.

System Optimization: They optimize designs for efficiency, reliability, and energy consumption, balancing performance with resource constraints in compact or power-limited systems.

Applications of Mechatronic Design Engineering

Mechatronic design engineers contribute to a wide range of industries:

Robotics: They design industrial robots, collaborative robots (cobots), and drones, integrating sensors, actuators, and AI for tasks like assembly, navigation, and object detection.

Automotive: Engineers develop systems like electronic stability control, autonomous driving modules, and electric vehicle powertrains, enhancing safety and efficiency.

Aerospace: They create flight control systems, satellite actuators, and unmanned aerial vehicles (UAVs), ensuring precision and reliability in high-stakes environments.

Manufacturing: Mechatronic engineers design automated production lines, CNC machines, and robotic arms, optimizing throughput in smart factories.

Medical Devices: They develop robotic surgical systems, prosthetics, and diagnostic tools, integrating precise control and sensor feedback for patient safety.

Consumer Electronics: Engineers design smart wearables, IoT devices, and home automation systems, creating compact, user-friendly solutions with real-time functionality.

Skills and Expertise Required

Mechatronic design engineers require a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, control theory, and software development is essential for integrated system design.

Technical Tools: Expertise in CAD (e.g., SolidWorks, CATIA), simulation tools (MATLAB/Simulink), and programming languages (C/C++, Python) is critical.

Problem-Solving: Engineers must analyze complex systems, identify performance bottlenecks, and devise innovative solutions under tight constraints.

Testing and Validation: Knowledge of testing methodologies, like HIL and SIL, ensures systems meet performance and safety standards.

Team Collaboration: Mechatronic engineers work with cross-functional teams, requiring strong communication to align mechanical, electrical, and software efforts.

Project Management: They manage project timelines, budgets, and deliverables, ensuring designs are completed efficiently and within scope.

Benefits of Mechatronic Design Engineering

The work of mechatronic design engineers offers significant advantages:

Innovation Leadership: Engineers drive advancements in automation, creating cutting-edge solutions for robotics, autonomous vehicles, and smart devices.

Efficiency and Cost Savings: Optimized designs and virtual prototyping reduce development costs by up to 20%, according to industry studies, and minimize material waste.

Enhanced Reliability: Rigorous testing ensures systems are robust, meeting safety standards in critical applications like aerospace and medical devices.

Sustainability: Engineers design energy-efficient systems, such as electric vehicle controllers, supporting global environmental goals.

Versatility: Their multidisciplinary expertise allows them to work across industries, from consumer electronics to industrial automation, enhancing career flexibility.

Challenges Faced by Mechatronic Design Engineers

The role presents several challenges:

Design Complexity: Integrating mechanical, electronic, and software components requires balancing competing constraints, increasing design and debugging complexity.

Resource Limitations: Embedded systems often have limited memory and power, demanding highly optimized firmware and hardware designs.

High Costs: Tools like MATLAB/Simulink, CAD software, and HIL platforms involve significant costs, challenging for smaller organizations.

Rapid Technological Change: Keeping up with advancements in AI, IoT, and materials requires continuous learning and adaptation.

Interdisciplinary Coordination: Aligning teams from different engineering disciplines can lead to communication challenges, requiring strong collaboration skills.

Future Trends in Mechatronic Design Engineering

The role of mechatronic design engineers is evolving with technological advancements:

AI and Machine Learning: Engineers are integrating AI into control systems for adaptive algorithms and predictive maintenance, enhancing robotics and automotive applications.

IoT Connectivity: Mechatronic systems are incorporating IoT for real-time data sharing, enabling smart factories and connected consumer devices.

Miniaturization: Advances in microelectromechanical systems (MEMS) support compact designs for wearables and medical implants.

Digital Twins: Engineers use digital twins for real-time system monitoring and optimization, improving lifecycle management in manufacturing and aerospace.

Sustainability Focus: Designing energy-efficient systems, like renewable energy controllers, aligns with global environmental priorities.

Conclusion

Mechatronic design engineers are pivotal in creating intelligent, automated systems that drive innovation across industries. By blending mechanical, electronic, and software expertise, they develop solutions like autonomous vehicles, robotic systems, and smart devices that are precise, efficient, and reliable. Despite challenges like design complexity and high costs, their use of tools like MATLAB/Simulink and CAD ensures robust, optimized designs. As AI, IoT, and sustainability shape the future, mechatronic design engineers will continue to lead, delivering cutting-edge systems that transform technology and enhance global progress.